Architecting a secure and scalable IoT data pipeline for industry 4.0

Architecting a secure and scalable IoT data pipeline for industry 4.0

Architecting a secure and scalable IoT data pipeline for industry 4.0

Why architecture matters for industrial IoT

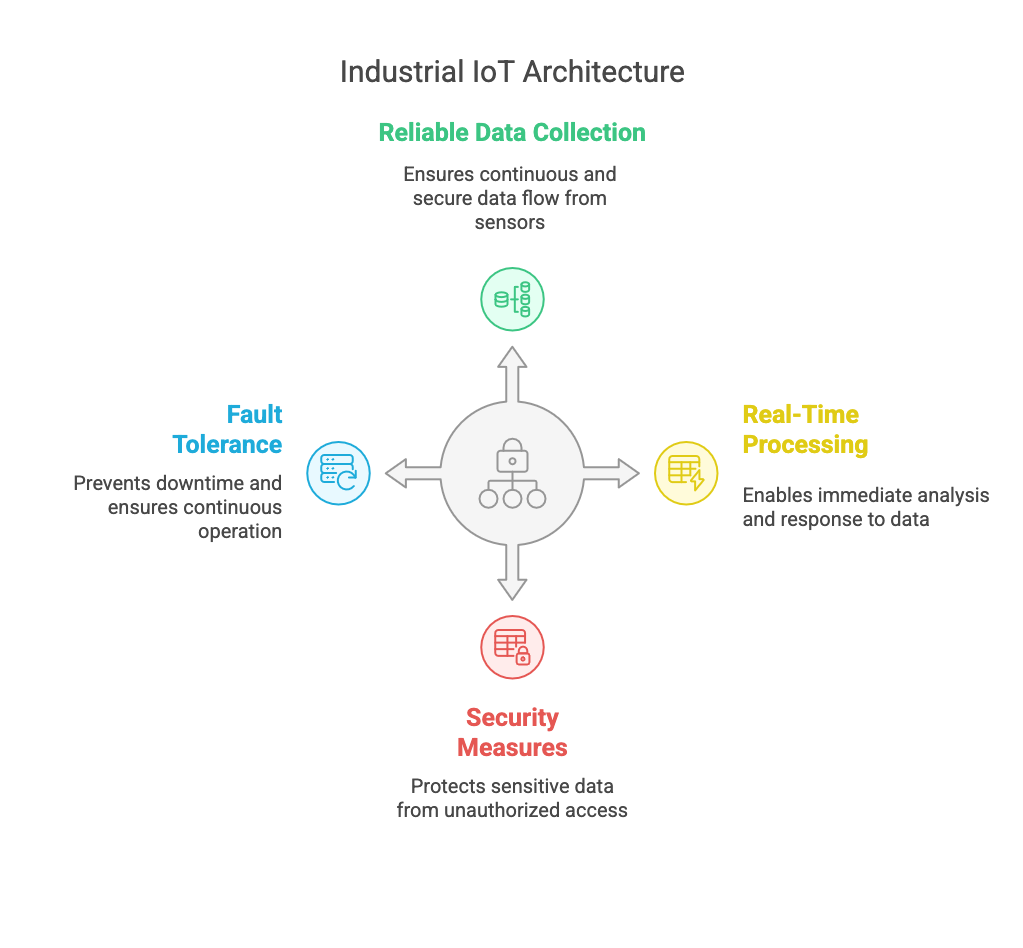

In massive industrial IoT deployments – think of thousands of sensors in a factory or across an energy grid – a secure, scalable architecture is critical. It’s not just about connecting devices; it’s about ensuring the deluge of data they produce is reliably collected, processed, and accessible in real time, without compromising security.

Industrial data flows are high-volume and continuous, with machines generating telemetry 24/7. A well-designed architecture prevents bottlenecks and downtime, which in turn prevents costly production halts. It also isolates and protects data, since IoT streams may include sensitive operational details or even personal safety information. For example, an IoT system monitoring a power plant needs to guarantee that control messages and sensor readings are transmitted with low latency and are shielded from unauthorized access or tampering (a security breach in such a system could have serious consequences).

Architecting for scale and security from the start means selecting the right tools and patterns to handle heavy loads and to compartmentalize data flows. Companies like Dattell emphasize fault-tolerant, highly optimized data infrastructure because industrial systems truly can’t afford an outage.

In short, the architecture is the backbone that allows IoT solutions to be trustworthy and enterprise-grade.

Ingestion at scale: Kafka and Pulsar in industrial IoT

A key layer in any IoT architecture is the data ingestion pipeline – the system that takes in millions of messages from devices and funnels them to where they need to go. Two proven technologies leading the pack here are Apache Kafka and Apache Pulsar. These open-source platforms act as high-throughput distributed messaging backbones, capable of handling millions of events per second from IoT sensors and machines.

In industrial contexts, Kafka and Pulsar are ideal because they were built with scalability and fault tolerance in mind. Kafka, for instance, has been used in manufacturing plants to stream real-time equipment data for analytics, supporting mission-critical use cases without downtime. It persists data to disk in a distributed cluster, ensuring that even if one node fails, the data is not lost – a must-have for exactly once delivery of important events.

Pulsar offers a similar distributed log approach but with a cloud-native design and multi-tenancy, which can be very useful when a solution must securely partition data by factory, region, or client. In fact, Pulsar’s architecture separates compute and storage, enabling dynamic scaling to handle usage spikes (like a surge of sensor alerts) without missing a beat.

For industrial developers, choosing Kafka or Pulsar means tapping into a rich ecosystem of connectors and tools – making it easier to integrate with IoT protocols (MQTT bridges are common) and to feed downstream systems.

The bottom line is that stream processing platforms like Kafka and Pulsar provide the reliable “data highway” for IoT: they ingest and buffer streams of readings, support real-time processing, and deliver data to consumers with sub-second latency. This ensures that even as your deployment grows from 100 devices to 100,000, the data pipeline scales out seamlessly and securely.

Real-time search and analytics: The role of Elasticsearch/OpenSearch

After data is ingested, it typically lands in a storage and query system where it can be searched, analyzed, and visualized. In industrial IoT, two popular choices are Elasticsearch and its open-source cousin OpenSearch. These systems are distributed search and analytics engines, and they excel at indexing large volumes of time-series and log data – exactly the kind of data IoT devices produce.

Why are they ideal for industrial applications? Because they combine storage, full-text search, and aggregation analytics in one platform. For example, a manufacturing company might index all sensor readings and production logs into OpenSearch and then easily query, “Show me all temperature sensor readings above 80°C in Reactor #3 in the last 24 hours,” with results in seconds.

Data infrastructure for IoT devices requires the ability to drill down and explore data in near real-time is crucial for troubleshooting and optimization on the plant floor. Both Elasticsearch and OpenSearch are designed to be horizontally scalable – companies can start with a few nodes and expand to dozens as data grows, without major re-architecture. They also support built-in replication and high availability, aligning with industrial needs for no single point of failure.

Moreover, these platforms integrate well with visualization tools (like Kibana or OpenSearch Dashboards), allowing engineers and managers to set up live dashboards for metrics like equipment efficiency, energy consumption, or quality yield. Imagine a control center dashboard where search queries continuously update graphs of vibration trends and AI-detected anomalies; that’s powered by these search engines churning through IoT data under the hood.

By using Elasticsearch/OpenSearch, industrial firms ensure that all the data captured via Kafka/Pulsar doesn’t just sit in a silo – it becomes immediately usable for insights, whether through automated analytics or ad-hoc queries. In essence, Kafka/Pulsar and Elasticsearch/OpenSearch complement each other: one handles streaming ingestion, the other handles searchable storage, together enabling a robust real-time analytics pipeline.

Built for industrial scale and security

Technologies like Kafka, Pulsar, Elasticsearch, and OpenSearch have risen to prominence in industrial IoT because they meet the demanding requirements of these environments.

Scale.

They are proven at handling the firehose of data from thousands of IoT sources without flinching, and they can scale horizontally by simply adding more cluster nodes – a critical factor as deployments grow.

Reliability.

Industrial systems often require 24/7 uptime and cannot afford data loss. These tools were designed for high availability; for instance, Kafka’s replication and Pulsar’s segment architecture both ensure data durability and system resiliency even if hardware fails.

Flexibility.

In a manufacturing or energy context, IoT data comes in many forms (sensor readings, images, logs) and must integrate with legacy systems and cloud services. Kafka and Pulsar offer integration connectors to bridge older protocols or databases, while OpenSearch and Elasticsearch support a variety of data schemas and APIs for developers to build upon.

Security.

Perhaps most importantly, these architectures can be secured to enterprise standards. Data can be encrypted in transit and at rest. Access control can be enforced at multiple levels – from limiting which devices can publish to Kafka topics, to setting role-based permissions on who can query the OpenSearch cluster.

Additionally, deploying these systems in siloed clusters (as Dattell does for each client) further enhances security: each organization’s IoT data pipeline runs isolated from others, eliminating any risk of data crossover. This isolation pairs well with compliance needs in sectors like energy (where data regulations are strict).

In industrial IoT, a secure and scalable architecture is not a luxury – it’s a prerequisite. By leveraging technologies specifically built for streaming data and real-time search, IT leaders can ensure their IoT deployments are resilient and ready for growth. The combination of Kafka/Pulsar with Elasticsearch/OpenSearch creates a powerful backbone that is up to the task of industrial-scale data – delivering information where it needs to go, as soon as it’s needed, all while keeping data protected. Such an architecture is what turns a collection of sensors into a true Industry 4.0 nervous system, capable of driving intelligent action at scale.